Msc1G4:Page6

TUD 4

Bewar Ahmed - Nino Schoonen

Introduction

In response to our collaboration with Arwin and the study of what the influence is of cell structures towards characteristics of the TPE surface we have set up this report. For our MSc 1 studio Non-standard and Interactive Architecture we are currently designing a furniture for joggers. For this furniture we came up with a set of different fitness-activities which all have their own requirements regarding the material and the softness of this material. In order to choose an adequate structure for the TPE for our furniture we’ve done some research. In this report we will firstly discuss the research method we have handled. Secondly we will state all our research results. After that we will end our report with a conclusion, a reflection and a discussion for a potential follow-up study.

The research method

For our research we handled the method of research through design. This means that we designed three

different patterns in Grasshopper. Each pattern with a different structure with the aim of manipulating

the softness of the material. After finishing the designs, we printed the patterns with a 3D printer. This in

order to examine the deformation, soft-, and hardness of the patterns after imposing a force on it.

The Research

Fragment We have chosen to focus on the area where people can do sit-up workouts, as this part of the furniture contains an interesting balance between structural requirements and softness for the end-user. After all, we don't want visitors to hurt themselves performing their workout; it is here where the right surface softness is required. A surface soft enough so it will feel comfortable, but also hard enough to perform the workout correctly. Our objective is to solve the requirements for piece of furniture first and prove them to work, as these systematics can be applied to the other parts of the model later on. Focusing on a small fragment was also necessary considering the time and manpower we had.

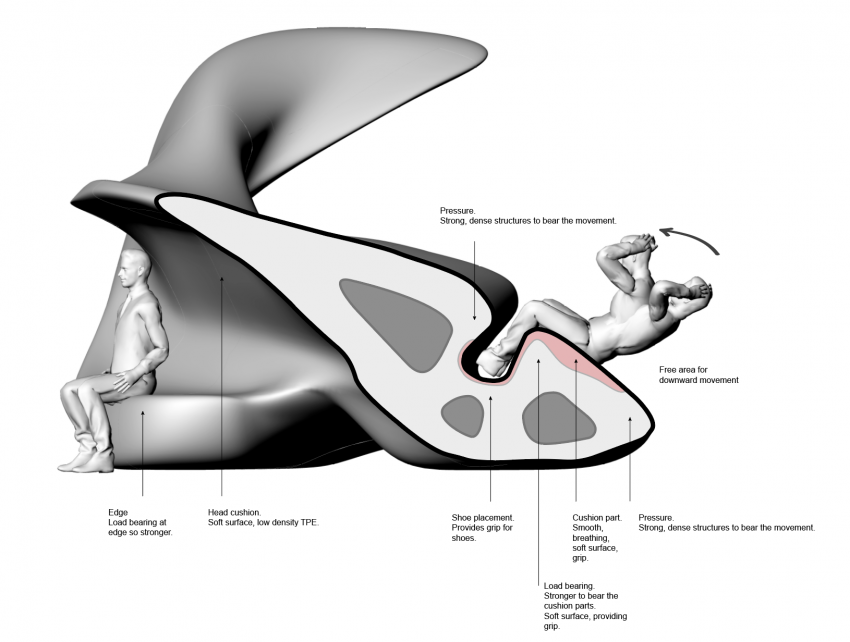

Requirements The furniture requires a combination of different material characteristics; load bearing parts, non-structural areas, hollow parts and surfaces that are designed harder or softer towards the type of activity being done. We started our research by mapping out the different requirements for the activity of a person doing sit-up movements. The figure below shows the different requirements of this fragment.

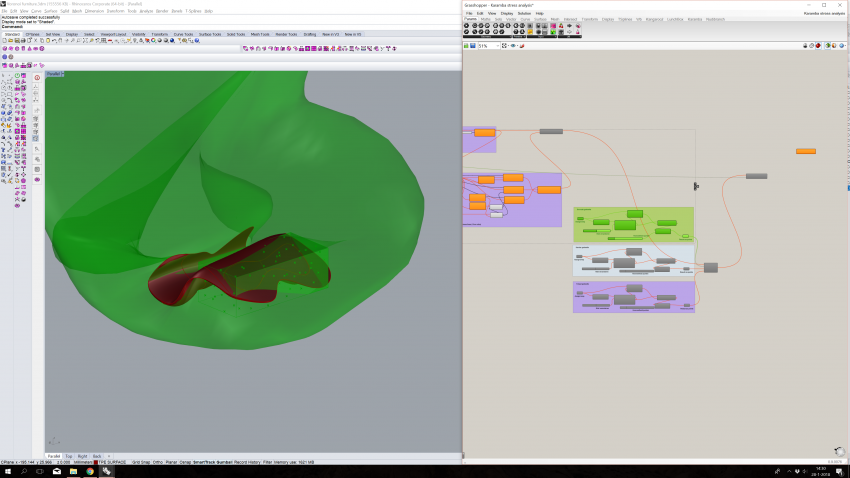

Making a stress analysis using the Grasshopper Plug-in: Karamba helped us to define structural density not only in the Macro form itself, but also on Micro scale.

Patterns

We've designed three different structures, each with a different bending behaviour. For inspiration we looked at nature; we can learn a lot from microscopic cell structures. Also, doing research towards pattern researches that have already been done by universities like MIT or professional companies like Arhold and haphazardly designing figures in the hope to invent something useful.

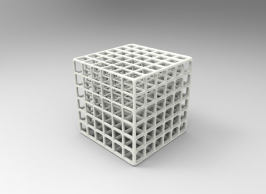

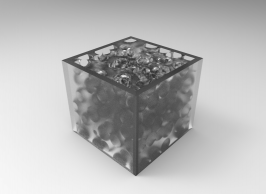

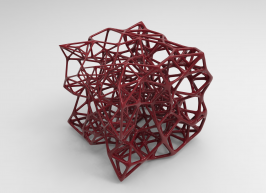

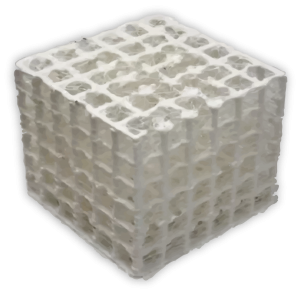

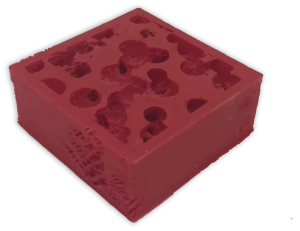

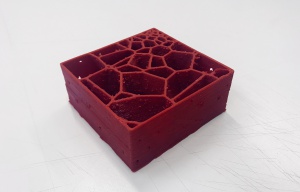

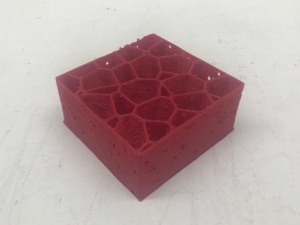

After this research we're made a selection of three different types of structures: a wireframe structure, a spongeous structure and a Voronoi wireframe structure.

The first, a wireframe structure, follows a simple box grid where the thickness of the wires are thinner where more softness is required. Thick wires make this structure stronger. The second, a spongeous structure, is a solid mass (infill 5%), with spheres reducing material. Spheres become bigger and occur more often on areas that need to be soften. Density results in a reduction of the cushion effect. Lastly, the Voronoi Wirestructure seemed impossible to print without supports, which could be solved by making manual printing toolpaths dealing with the 45-degree printing problem. With a little help from Arwin Hiddink, we eventually solved this printing problem as he knew how to deal with these toolpaths.

It is crucial for us to make a physical experiment print in order to give a good judgement about the behaviour of the pattern.

3D printing

We've spent a great deal of our time researching and designing different patterns. It was our goal to find which patterns have the best characterictics when dealing with pressure, while also dealing efficiently with material usage. It has been a big task already learning how to get these (still rather simple) patterns coded into Grasshopper, as the logic and work-flows of this program was still new to us. Our next step, after designing the three patterns, was to print out what we've had created.

As printing with TPE is something not usual, printing with TPE was a research on itself. Luckily we could get some help from Serdar Asut from the Building Technology Print Lab; printing with flexible TPE material is something they haven't experimented with so far, and they were very interes . A more detailed explanation of our Pattern Research can be found on our pattern research tab.

Results

The best way to visualize our results is with the use of video material. The three videos below give a quick timelapse of our 3D-Printing process, finalizing with the structural bending behaviour towards pressure.

TPE 45D Experiment: Semi-Flexible TPE, Wireframe structure

TPE 85A Experiment: Flexible TPE, Spongeous structure

TPE 85A Experiment: Flexible TPE, Voronoi structure

Conclusion

.1 TPE 45D Experiment: Semi-Flexible TPE, Wireframe structure

It was right after our first wireframe experiment that we've noticed semi-flexible TPE (flexibility 45D) is way too strong for what we want to achieve. It is not (only) a matter of structure with this semi-flexible TPE, but material characteristics seemed to be of way more importance. This print recieves its flexibility through (accidental) mistakes which occured during the printing test: certain horizontal wires are not printed which make the structure actually bend in quite well, while remaining (almost) completely stiff by itself. Problematic can be the structural deformation on a bigger scale.

.2: TPE 85A Experiment: Flexible TPE, Spongeous structure

A flexibility value of 85A felt directly much softer. Sitting on this piece of 10x10x5 cm already felt comfortable while the structure is deforming slightly. A great value of this spongeous structure is that the printer can always print these spheres on top of eachother. This avoids toolpath manipulation that occured during the Voronoi test print.

.3: TPE 85A Experiment: Flexible TPE, Voronoi structure

The Voronoi structure was much harder than we expected it to be. Putting pressure on top of the structure barely shows any deformation, and feels not nearly as soft as the sponges structure we've printed earlier. Although putting the structure on the side allows the bigger Voronoi cells to buckle a lot, resulting in softness, although this softness is not as comfortable as we can achieve with the Spongeous print. In contrary to the Spongeous structure, this Voronoi structure requires less material, at the cost of comfort. The dense area of the structure proved to be very capable for dealing with load bearing parts, even with a flexibility property of 85A.

Choice of structure

Printing out these different structures proved their value because it made us come up with a decision very different than we expected it to be in the first place. We've come up to the decision to create our soft areas with the Spongeous structure. Yes, this structure uses more material than its variants but testing them out resulted in a way more comfortable surface than the other two variants. It is for this reason we only apply a soft, comfortable surface on the areas where it needs to be softer. We do want to continue with the Voronoi structure as well, to use it as our load bearing structure. Parts of the model where people don't need to sit on don't have to be soft and smooth and the Voronoi structure proved its value when dealing with forces and material efficiency. For this load bearing skelet TPE usage is not necessary, as this seems to be four times more costly than ABS or PLA filaments.

Discussion

The presentation of Foteini Setaki (given on Tuesday the 31st of October) inspired us with the idea of using recycled plastic for our furniture. Creating our furniture out of plastic waste collected from the Kralingen Park was our first intention. Using it as the structural material in combination with the softer TPE surfaces. For this reason, we did some research into using recycled plastic as a filament for our 3D prints. The conclusion of our research was, in short: Recycling plastic is an intensive process that takes a lot of time and energy. The process includes collecting, washing, shredding, adding chemicals lastly, reforming the plastic. Beside the insensitivity and the time taking process recycled plastic hasn’t the same characteristics as TPE. The most important characteristic is the flexibility of the material. Shortly that is the reason why there is not chosen for recycled plastic as main material.

At the start of this course we’ve analyzed the activity on the site during different times of the day. Knowing

who is around the area helped us define what target group we should design for: a furniture for runners.

After this exercise we started to remap the experience of going for a run (as explained in the lecture of

Milica Pavlovic). We observed that Kralingen is an amazing area for runners, but giving runners the

option to do a run combined with sport-exercises on a parametric furniture would be an interesting

addition for runners. User remapping helped us define this concept.

Continuing this approach, we’ve came up with a set of passive workouts. We zoomed into these activities

by looking at the movements happening doing these activities and the relation to the surface and the

human body. We translated these activities into sections, which we used to make a complete form using

clay models.

Structural Optimization for Materially Informed Design to Robotic Production Processes - H. Bier and S. Mostafavi, 2015

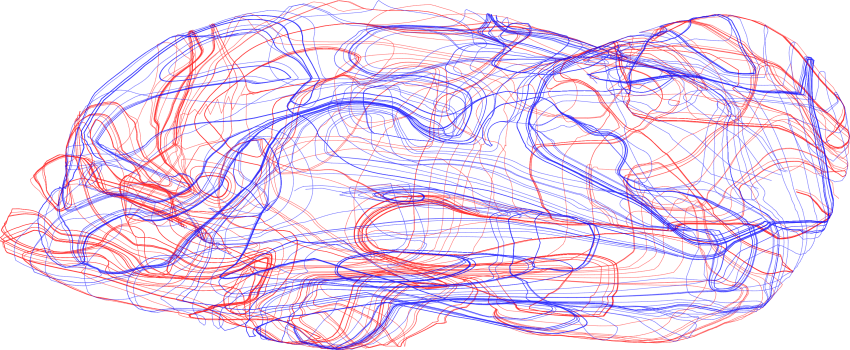

The additive production approach. Mapping stress lines using Karamba gave us insights in the structural forces and tensions happening in our macro geometry. This exercise enabled us to generate a point cloud inside our geometry, based on force loads and tensions. By optimizing point cloud densities based on forces on the furniture (generated with Karamba stress lines) we could optimize the Voronoi cell size for the load bearing structure. Dense clouds of points would result in a division of a big Voronoi cell into many smaller cells, which gives stiffness to this area which we needed for load bearing parts. This way we are thinking (according to the essay) in the so-called demand driven architecture; optimizing our furniture by applying more material where necessary. Of course, load bearing characteristics are just one of the demands we need to deal with, rain, usability patterns, assembly methods et cetera are also demands that could be added in later stages. We focused on the efficiency of material usage and load bearing demands first, because we felt like this was a logical bottom-up approach, adding further demands later onwards. Karamba's stress analysis did not only help us to optimize the load bearing structure. The information Karamba gave us is also used to optimize the soft cushion area the TPE surface creates. While manually assigning the area of the TPE surface with T-Splines, cloud densities in this surface were also made, which is essential for making the cushion effect to be bigger where necessary, or almost no cushion effect at all. Different T-Spline boxes were created to assign the transition of cushion effect, by assigning different cloud densities manually, see the picture below.

We've experimented a lot with (semi-)flexible 3D-printable TPE. Designing a variety of structures and printing these at the Building Technology Print-Lab, made us realise even better that digital design, digital production and material characteristics can't be seperated from eachother. Preparing a design in the computer and trying to get exactly this design printed in reality was almost impossible Doing such experiments is of a great value because now we can judge the materials bending behavior and learn from the production process, manipulating the patterns from these conclusions and we even combine these structures with eachother in order to generate an even more efficient structure. (Bier & Mostafavi, 2015)