Difference between revisions of "project12:W2Group1B 3"

(→Production) |

(→Process and Reflection) |

||

| (15 intermediate revisions by one user not shown) | |||

| Line 3: | Line 3: | ||

=='''G1 B - Urban Farmers'''== | =='''G1 B - Urban Farmers'''== | ||

| − | Hidde Manders - Dafne | + | Hidde Manders - Dafne Swank - Mary Ann Berendson - Arav Kumar - Szymon Lapaj |

| Line 30: | Line 30: | ||

[[File:IMG 20171019 232145.jpg|400px]][[File:IMG 20171019 234921.jpg|400px]] | [[File:IMG 20171019 232145.jpg|400px]][[File:IMG 20171019 234921.jpg|400px]] | ||

| + | |||

| + | [[File:IMG 20171020 001645.jpg|800px]] | ||

[[File:IMG 20171020 005745.jpg|400px]][[File:IMG 20171020 013907.jpg|400px]] | [[File:IMG 20171020 005745.jpg|400px]][[File:IMG 20171020 013907.jpg|400px]] | ||

| + | |||

| + | [[File:IMG 20171020 020132a.jpg|800px]] | ||

| + | |||

| + | == Production Videos == | ||

| + | |||

| + | [[File:27L final.gif|800px]] | ||

| + | |||

| + | [[File:31L final.gif|800px]] | ||

| + | |||

| + | [[File:Combined 1.gif|800px]] | ||

| + | |||

| + | [[File:Combined 2.gif|800px]] | ||

| + | |||

| + | == Final Render == | ||

| + | |||

| + | [[File:Render worms (1).jpg|800px]] | ||

| + | |||

| + | == Process and Reflection == | ||

| + | |||

| + | The workshop consisted in the parametric design and robotic production of a fragment of urban furniture in the context of Dessau’s Elb river. The first days we developed the concept of adaptation to the natural environment and the functionality for different users other than humans such as insects, birds, etc. Based on these ideas and on 3 different sitting positions we designed a form that adapted to those general parameters. | ||

| + | |||

| + | After we had a general shape of urban furniture we applied the Voronoi principle on a selected fragment of it. This principle is present throughout many systems in nature: the idea of fragmentation that generates different degrees of density and porosity. The parameters used to determine the areas with higher density or porosity in the fragment’s surface were the force lines of tension and compression which were obtained through a plug-in in grasshopper. | ||

| + | |||

| + | Finally we applied grasshopper scripts to generate the Kuka robot’s path of movement to hot wire-cut the basic shape and then mill the details of the surface, both bumps and holes. At the start of the hole-drilling stage, however, we realised that the drill’s scale and ‘bumps’ were not proportional, so we decided to only drill a few holes to avoid destroying the texture and form obtained. | ||

| + | |||

| + | To conclude, the workshop was a very helpful and didactic way to get introduced to parametric design and robotic fabrication because we got to create an object in a very short period of time with hands-on experience. | ||

Latest revision as of 12:21, 2 November 2017

G1 B - Urban Farmers

Hidde Manders - Dafne Swank - Mary Ann Berendson - Arav Kumar - Szymon Lapaj

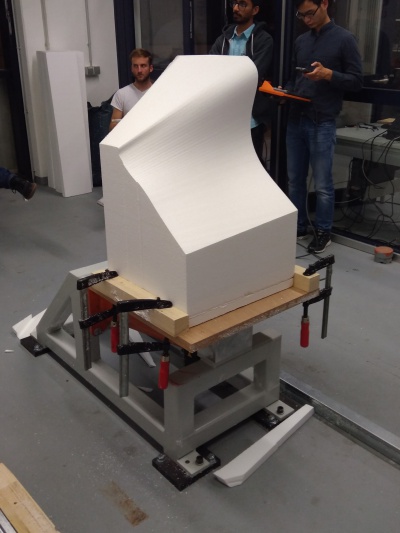

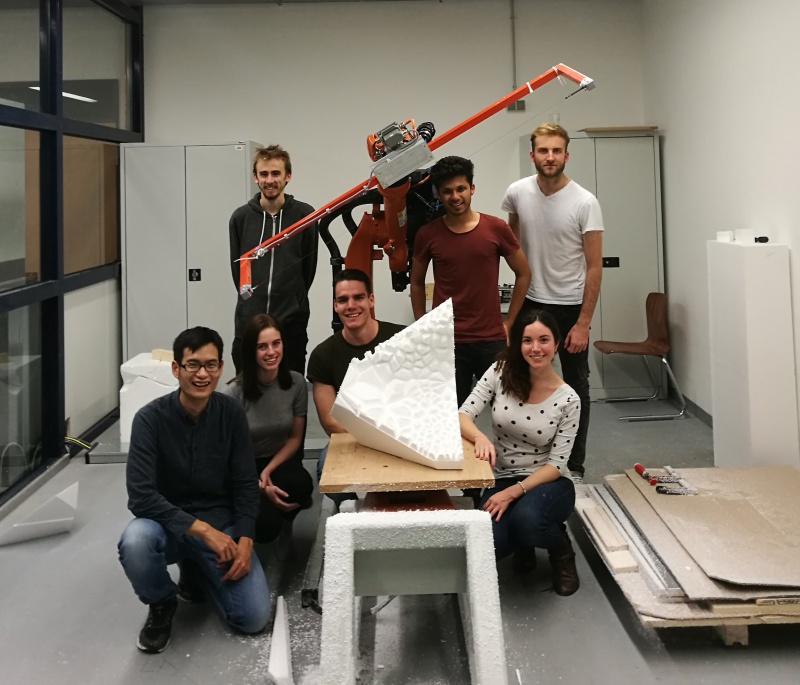

Production

Production Videos

Final Render

Process and Reflection

The workshop consisted in the parametric design and robotic production of a fragment of urban furniture in the context of Dessau’s Elb river. The first days we developed the concept of adaptation to the natural environment and the functionality for different users other than humans such as insects, birds, etc. Based on these ideas and on 3 different sitting positions we designed a form that adapted to those general parameters.

After we had a general shape of urban furniture we applied the Voronoi principle on a selected fragment of it. This principle is present throughout many systems in nature: the idea of fragmentation that generates different degrees of density and porosity. The parameters used to determine the areas with higher density or porosity in the fragment’s surface were the force lines of tension and compression which were obtained through a plug-in in grasshopper.

Finally we applied grasshopper scripts to generate the Kuka robot’s path of movement to hot wire-cut the basic shape and then mill the details of the surface, both bumps and holes. At the start of the hole-drilling stage, however, we realised that the drill’s scale and ‘bumps’ were not proportional, so we decided to only drill a few holes to avoid destroying the texture and form obtained.

To conclude, the workshop was a very helpful and didactic way to get introduced to parametric design and robotic fabrication because we got to create an object in a very short period of time with hands-on experience.