Difference between revisions of "W12022"

(→CONTENT & APPROACH) |

|||

| Line 33: | Line 33: | ||

The approach involves Design-to-Robotic-Production-Assembly and -Operation (D2RPA&O) methods with the aim to improve process- and material-efficiency in construction as well as embed intelligence in building processes and buildings by (1) robotically optimising material distribution and assembly, (2) by assembling component using Computer Vision (CV) and Human-Robot-Interaction (HRI), and by (3) embedding sensor-actuators that are enabling interaction between users and physically built environment. | The approach involves Design-to-Robotic-Production-Assembly and -Operation (D2RPA&O) methods with the aim to improve process- and material-efficiency in construction as well as embed intelligence in building processes and buildings by (1) robotically optimising material distribution and assembly, (2) by assembling component using Computer Vision (CV) and Human-Robot-Interaction (HRI), and by (3) embedding sensor-actuators that are enabling interaction between users and physically built environment. | ||

| − | For additional information | + | For additional information read brief (https://docs.google.com/document/d/1mqYeruN7tJAUMmY5oNKGkH9jguTbqk9jMy8f8rJHhKI/edit). |

<br> | <br> | ||

<br> | <br> | ||

Revision as of 09:00, 20 January 2022

MSc 2 (BK-CiTG-EWI-3ME) 2022: Interactive Furniture

CONTENT & APPROACH

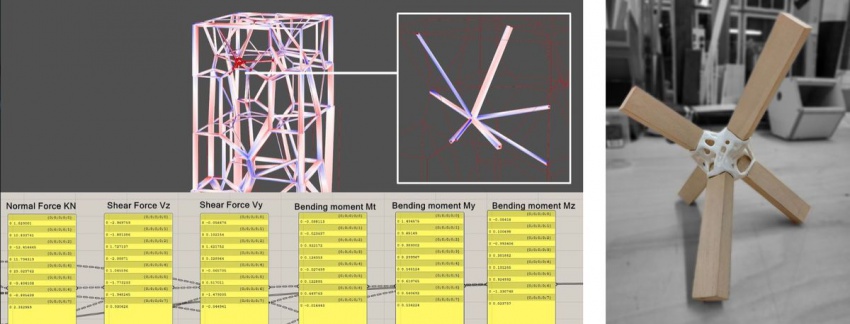

The focus of both courses will be on the development of urban furniture. The furniture components range in size and functionality from outdoor climbing walls to canopies or similar. They are designed with structural, functional, environmental, and assembly considerations in mind. The structure is displaying degrees of porosity, where the degree and distribution of porosity i.e. density are informed by functional, structural and environmental requirements, while taking into consideration both passive (structural strength, physical comfort, etc.) and active behaviours (interaction, etc.).

The approach involves Design-to-Robotic-Production-Assembly and -Operation (D2RPA&O) methods with the aim to improve process- and material-efficiency in construction as well as embed intelligence in building processes and buildings by (1) robotically optimising material distribution and assembly, (2) by assembling component using Computer Vision (CV) and Human-Robot-Interaction (HRI), and by (3) embedding sensor-actuators that are enabling interaction between users and physically built environment.

For additional information read brief (https://docs.google.com/document/d/1mqYeruN7tJAUMmY5oNKGkH9jguTbqk9jMy8f8rJHhKI/edit).

DELIVERABLES

1. PPT presentation (uploaded to the wiki) showing project theme, design strategy, and design from schematic to developed and materialisation design levels.

2. 1- to max. 2-minutes video of D2RP&A process uploaded to the wiki.

3. Report (±1500 words) consisting of textual and photo/graphical documentation of physical prototypes and design to fabrication process developed during the course.

4. Clean Rhino and Grasshopper files and refined version D2RP&A procedures.

5. Scaled models, 1:1 prototypes, and/or tests.

SCHEDULE

Schedule is available here: https://drive.google.com/drive/folders/187qJYvB60te0ULkPsCvWqiZY-KmglCpm.

TEAM

Henriette Bier (BK), Seyran Khademi, Casper van Engelenburg (BK & EWI), Mariana Popescu (CiTG), and Luka Peternel, Micah Prendergast, (3ME) : Computational Design and Design-to-Robotic-Production and -Assembly (CD and D2RP&A), Computer Vision (CV), and Human-Robot-Interaction (HRI)

Vera Lászlo (BK): technical support and coordination

PARTNERS

Vincent Cellucci (Library TU Delft), Arwin Hidding (Ducth Growth Factory)

STUDENTS

Groups 1-3